EFI 01: GLOW WIRE TEST APPARATUS (IEC 60695-2-10).

EFI 01: Glow Wire Test Apparatus (IEC 60695-2-10).

The equipment development from SECOM is fully automated test equipment for fire hazard testing as per IEC-60695-2-10, controlled by microcontroller.

Main Specifications

- done Temperature Programmable up to 999°C.

- done Programmable Test Time.

- done Programmable Observation Time.

- done Test 100% automatized.

Our EFI 01 (Glow Wire Test Apparatus) is fully automated, controlled by microcontroller, for tests related to the risks of fire in electrical devices, according to the test method of incandescent filament (or incandescent tip)

IEC 60695-2-10 – Fire hazard testing. Part 2: Test methods – Glow-wire test and guidance.

The best method for testing electro technical products with regard to fire hazard is to duplicate exactly conditions occurring in practice.

In most cases this is not possible. Hence, for practical reasons, testing of electro technical products for fire hazard is conducted by simulating as closely as possible actual effects occurring in practice.

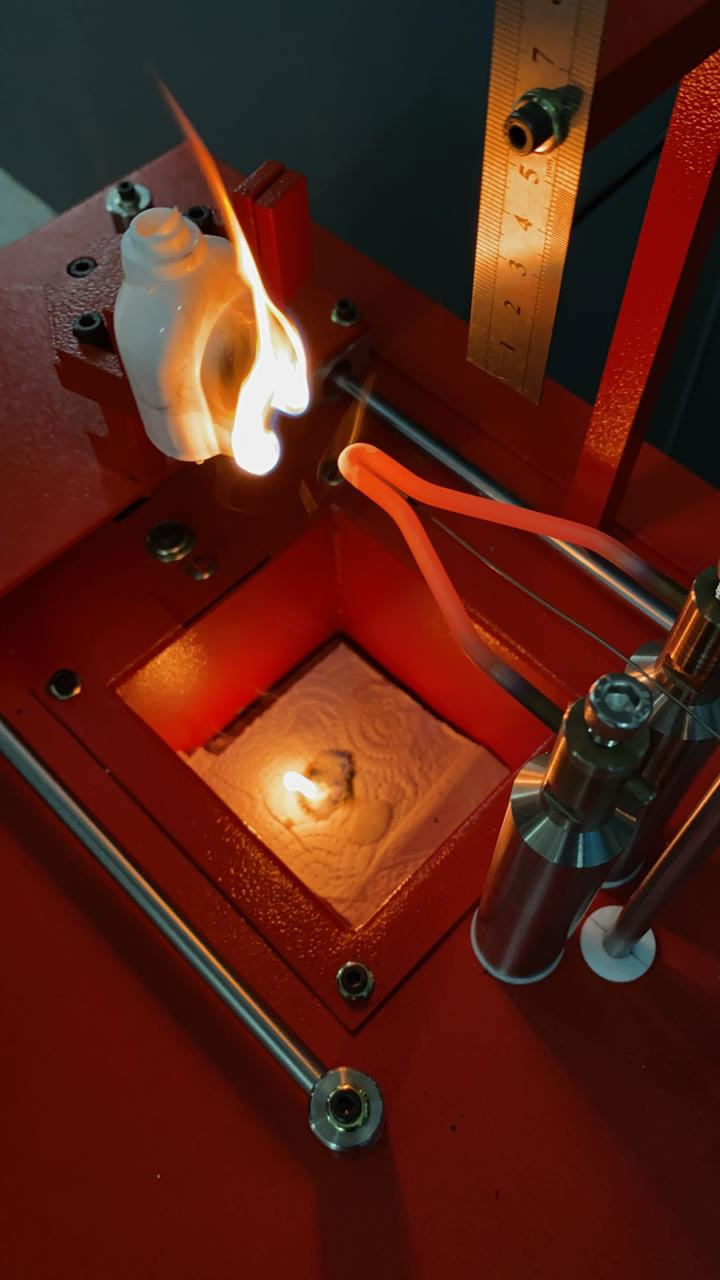

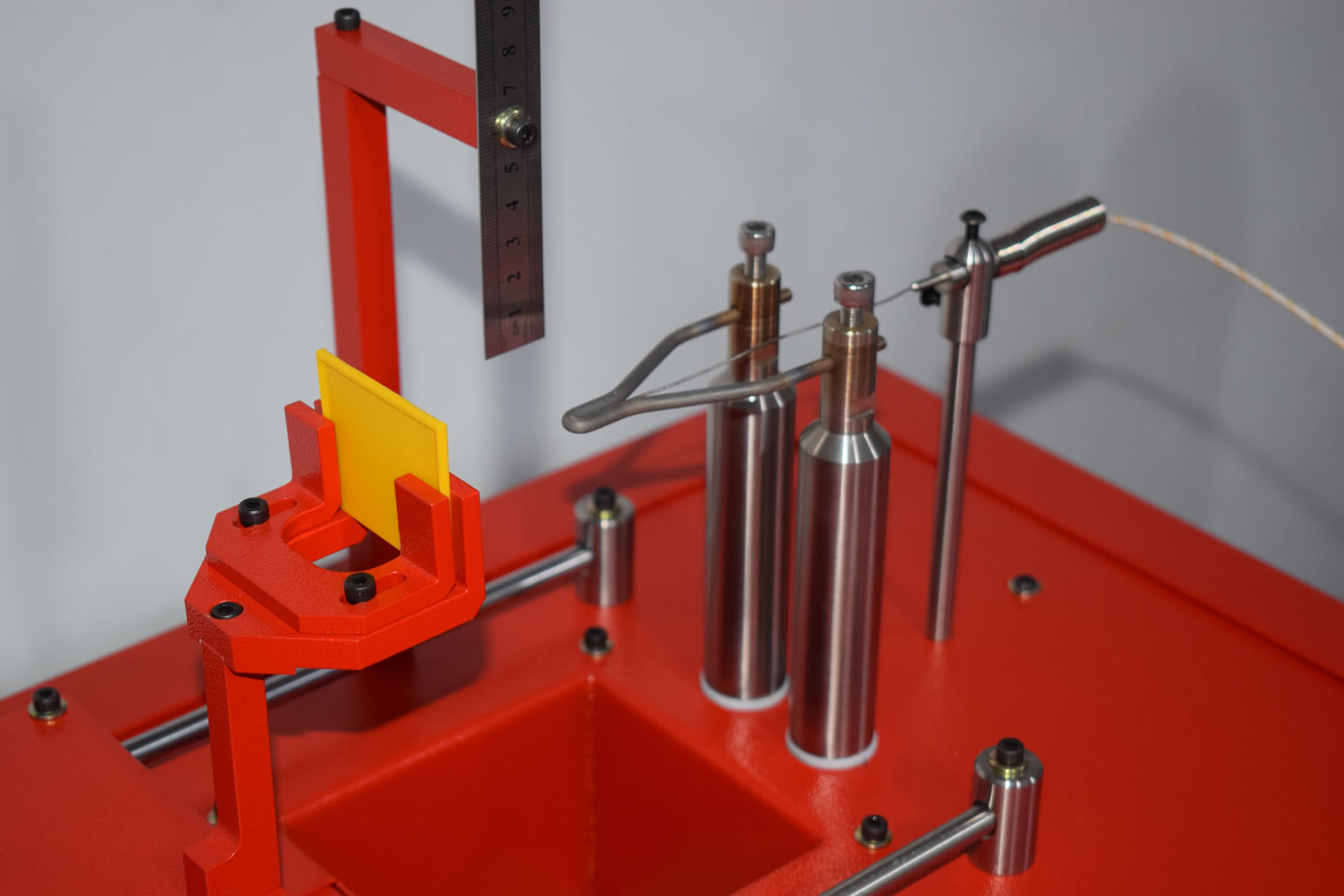

The Glow Wire Tester (EFI 01) has a loop of resistance wire is electrically heated to a specified temperature and the specimen being tested is brought into contact with this heated wire with a defined horizontal loading.

Observations and measurements are made to evaluate the fire hazard presented by the specimen during exposure to elevated temperatures.

The test described in IEC 60695-2-10.

Our Glow-wire flammability test according to IEC 60695-2 is fully automated, controlled by microcontroller.

You only should set:

- done Temperature Test.

- done Test Time.

- done Observation Time.

- done Put the sample in the car and press the Start button. The sample holder will begin to move forward until glow loop touch and, after the elapsed time settings, the car will go back to the starting position.

EQUIPMENT SPECIFICATIONS

done Contact Time (Sample with the Loop Wire).

done Observation Time.

done Delay Time: Changing this time you can modify the depth of penetration.

add Test 100% automatic.

add Plug & Play: only you must connect it to the power supply, turn on and begin it to realize tests.

add Electrically heated by current transformer 150 A, to a predetermined temperature from 0 to 999 ºC

add Loop Wire Nickel/Chromium (80:20), Ø 4mm, shaped as specified in standard.

add Temperature is measured by a Thermocouple Type K (Ø 0.8mm) and is indicated on digital display.

add Test sample contact force against glow wire preloaded to 1.0N (+/-0.2N).

add Penetration depth 7mm (+/- 0.5mm) and flame height mechanical and electronically controlled.

add Digital timer to control Glow wire application time, test duration.

add Programmable temporized of the test sequence.

add Display LCD.

add Stainless steel rule.

add Automatic, motorized forward and reverse motion of test specimen.

Weight: 35 Kg.